The shaft coupling is one of those small components that few people think about – until something goes wrong. Suddenly, vibrations, wear or even breakdown occur. Then it doesn’t matter how powerful your engine is or how advanced your machinery is – if the coupling doesn’t do its job, the entire system will fail.

But the right coupling can make a big difference. It can ensure smooth power transmission, dampen vibrations and compensate for alignment errors. So how do you know which shaft coupling is the best for your application? In this guide, we will help you make the right choice, so you can optimize both the performance and lifespan of your machine components.

What does your coupling need to do?

Depending on the application, shaft couplings can fulfil several important functions:

The more clearly you define your needs, the easier it will be to choose the right coupling type.

Which type of shaft coupling suits your application?

There are several different types of shaft couplings, each with unique characteristics. Here are some of the most common:

| Type | When should you choose this one? | |

|---|---|---|

| Tooth coupling |  |

When you need a torsionally stiff and backlash-free coupling with high performance. Withstands uneven loads and vibrations. |

| Spline coupling |  |

An economical alternative that dampens torsional vibrations and can handle relatively large assembly deviations. Requires no maintenance. |

| Spiral coupling |  |

For applications where you want to eliminate alignment errors and radial displacements. Perfect for encoders, stepper motors and servo drives. |

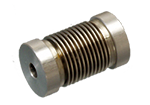

| Bellows coupling |  |

If you need extremely high torsional rigidity and precision. Common in servo drives, positioning equipment and encoder systems. |

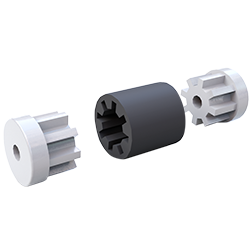

| Jaw coupling |  |

Three-part coupling that dampens vibrations, torque shocks and compensates for assembly errors. Has elastic elements and is galvanically isolated. Suitable for motor drives, pumps and positioning applications. Also available for high torques. |

| Universal joints |  |

Enables torque transmission between shafts with angular misalignment. Single link handles up to 45°, double link up to 90°, depending on speed. Available in plain and needle bearing versions as well as in stainless steel. |

| Double-loop coupling |  |

Developed for maximum flexibility and compensation of axial, radial and angular errors. One of our most cost-effective couplings with high reliability. |

By choosing the right coupling, you can avoid problems such as backlash, wear and inefficient power transmission.

Set screw or clamping hubs – which is best?

Shaft couplings are usually mounted with either a set screw or a clamping hubs. Which solution you choose depends on your type of operation:

Set screw: A good choice if the coupling is to be mounted on a shaft with a chamfer or keyway. However, it can be difficult to dismantle.

Clamping hubs: Recommended for reversible drives, as it provides a more stable attachment and reduces the risk of damaging the shaft. Clamping hubs also simplify dismantling during service.

Other important factors to consider

Will the coupling fit in the space available?

Wide range for all needs

Regardless of what type of coupling you need, Mekanex offers a wide range of solutions adapted to different industries and applications. We have couplings for shaft diameters from 3 mm up to 100 mm, and if you need a customized solution, we can in many cases deliver this within just a few days.

Our couplings handle torques from a few Newton centimetres up to 27.000 Nm, and we have products that can handle both low and very high speeds – up to 40.000 rpm, where balancing may be required.

To ensure easy assembly and a durable attachment, we offer couplings with both set screws and clamping hubs. For reversible drives, we always recommend clamping hubs, as they provide a more stable and gentle attachment.

We know that the right coupling can be crucial for a reliable and cost-effective machine solution. That’s why we make sure that you get the solution that best meets your needs – quickly and smoothly.

We help you choose the right coupling

Choosing the right shaft coupling can seem complicated, but we make it easy for you! Our experienced engineers will help you find the best solution based on your requirements and application needs.

Contact us today and we will ensure that you get a coupling that maximizes both performance and service life!

Phone number: +372 613 98 44

Email address: raul.maripuu@mekanex.ee