For more than 50 years, HepcoMotion has built its reputation as a manufacturer of linear guides, ring systems and track systems – with a focus on delivering solutions that meet tough demands in industrial environments. In the Baltics, the entire range is represented by Mekanex.

During these years, we – Mekanex and HepcoMotion – have grown together, learned from each other and delivered system solutions to customers in a number of different industries.

So, what makes HepcoMotion’s offering so strong? When reliability, precision and high productivity are at stake, the choice of linear guidance is crucial. Here, HepcoMotion – a pioneer in linear technology – has been offering guides, rings and track systems that meet the industry’s toughest requirements for over 50 years.

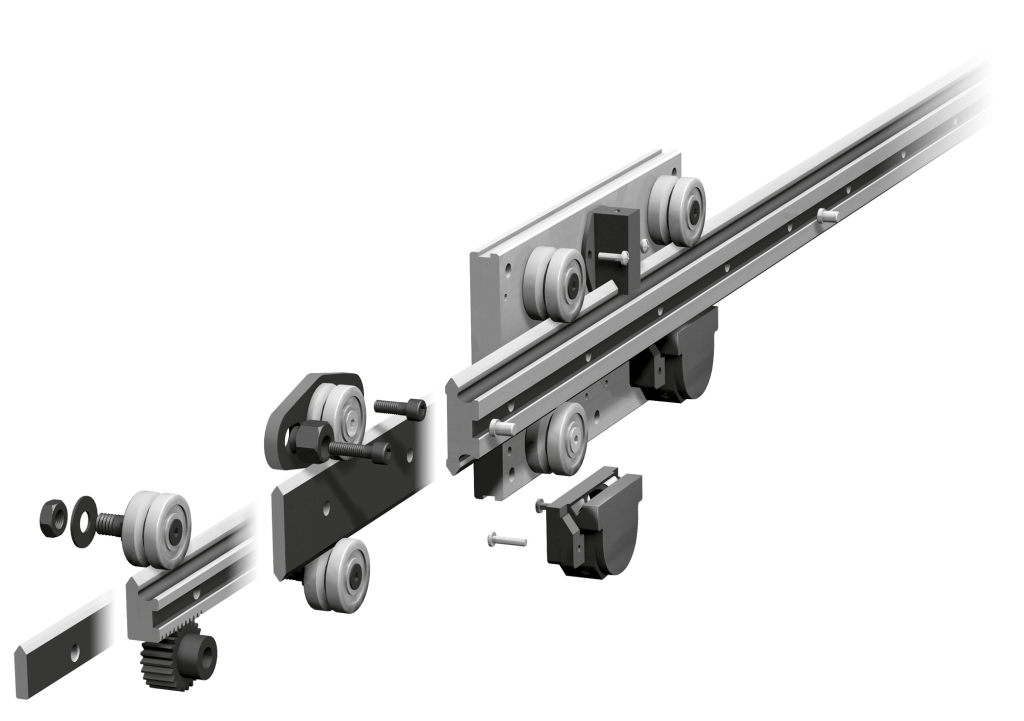

The V-wheel principle – self-cleaning and maintenance-free

The basis of many HepcoMotion systems is the proven V-wheel design, where roller/bearing surfaces form a V-profile against the sliding surface. This provides a self-cleaning effect. Dirt and particles are pressed out of the contact surfaces as the wheels move, meaning the system effectively cleans itself – ideal in environments where hygiene is crucial. The design also offers several advantages:

These properties make V-wheel technology well suited for applications in food, medical technology and other sensitive environments, where both hygiene and reliability are required.

Modular and flexible construction system.

Focus on durability and flexibility

Another advantage is the service life. When a bearing starts to wear out, it can easily be adjusted or replaced individually without having to replace the entire system – something that is not possible with ball rails. For really heavy loads, there is the HDS2 Heavy Duty system, with needle bearing blocks and self-cleaning contact surfaces.

All components are available in both standard and stainless-steel options, and can be run unlubricated if the application requires it.

Quiet operation and complete solutions

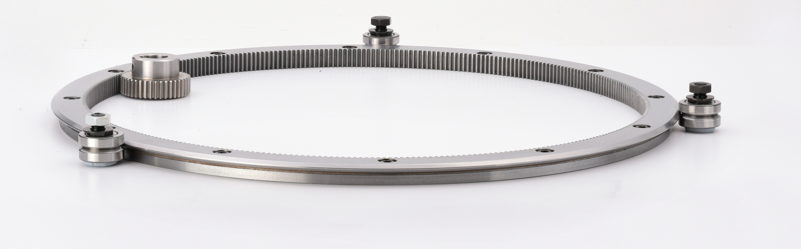

V-track systems are generally quieter than their ball rail counterparts, which is important in sensitive production environments with requirements for a quiet environment. But HepcoMotion offers more than just rails:

Example of ring and bearing with internal gear drive.

Why Mekanex and Hepco have collaborated for over 40 years

That a collaboration lasts for decades – that says something about both product quality and trust. Here are some important reasons why our relationship with HepcoMotion continues to be strong:

Deep technical knowledge and joint development

Over the years, we at Mekanex have developed strong application expertise in linear guides. By working closely with HepcoMotion, we have been able to influence technical solutions, optimize designs for the needs of Swedish customers and ensure that the product portfolio is relevant to the market.

Wide range and flexibility

HepcoMotion’s product range allows us to offer complete solutions – from lightweight precision systems to extremely robust heavy-duty applications. For a customer with varying needs, this gives us the opportunity to be a complete supplier.

Quality and reliability in practice

When customers demand minimal downtime, long service life and hygienic operation (for example in food or medical technology), HepcoMotion’s systems have proven time and time again that they can do it. This builds trust and loyalty.

Support, service and documentation

With Mekanex as a distributor in the Baltics, customers have access to local technical support, CAD files, catalogues and advice to find the right solution. In addition, this strengthens the partnership and relationship between Mekanex and HepcoMotion, demonstrating that we stand for long-term sustainability and responsibility in the supply chain.

All this allows us to deliver long-term and customized solutions that you as a customer can rely on, year after year.

Want to know more?

Contact us and we will be happy to help you!